Precision Explained: The Laser Cutting Process

In the field of steel and mild steel fabrication, laser cutting is a pivotal process for achieving precision and efficiency.

In the field of steel and mild steel fabrication, laser cutting is a pivotal process for achieving precision and efficiency.

Find out more about the unveiling of our new advanced equipment and the difference they will make to your business

We’re excited to announce the news of an additional value offering to our suite of fabrication services! The team at

Discover QSM’s extensive range of machinery that caters for all metal bending services. QSM have a long history in the

Join us as we take a look back at the past 40 years’ of QSM! We can’t believe that this

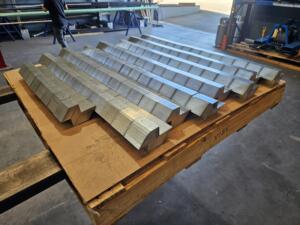

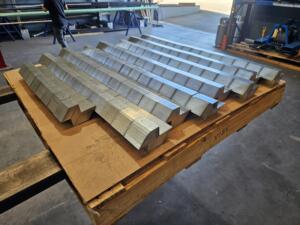

Find out more about QSM Fabrication’s laser cutting, 3D laser cutting and smart bending services available now! The fabrication

Your expert industrial welders and laser cutting specialists in Perth Laser cutting is a technology that has been used

As we head towards another new year, we wanted to set you up with the fabrication information to keep top

QSM Fabrications’ roots date back to 1992 when Giovanni (John) Siciliano founded the business delivering a variety of steel-related products

With the economic boom probably past its peak, Western Australian steel fabricators are going through a bit of a rough