Perth’s Laser Services

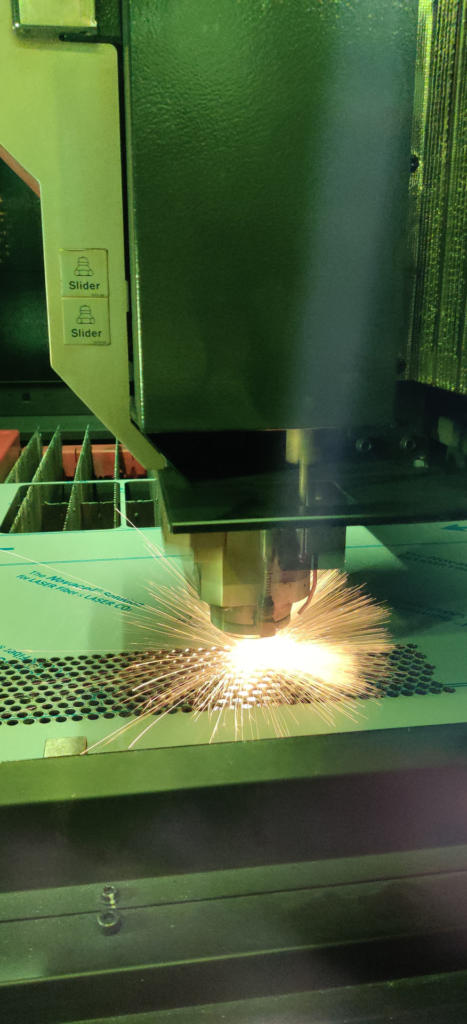

Utilising state-of-the-art technology and programming soware, QSM offers high quality laser cutting, 3D laser cutting and smart bending. QSM Laser provides incredible precision when it comes to tubular, structural and long product sections and the smart press has changed the bending game!

Interested in using our lasers? Find out more about what they can do.